KARACHI: A school bag slung over his shoulder and a dream in his eyes, little Ali Gul would often stop by at the coal mine where his brother worked on his way to school each morning in the mining town of Sinjawi in Pakistan’s southwestern Balochistan province.

There he would sit for a while among the acrid smell of burning coal and quietly watch the miners, their faces caked in toxic dust and dried sweat from working up to 1,200 feet underground on grueling 8-hour shifts.

As he would walk off to school moments later, Gul couldn’t help but wonder if he too might end up working at the mines like his brother Gul Muhammad and so many other relatives and friends from his village in Ziarat district, a few kilometers from the coal-mining center of Duki.

Instead, Gul traveled far away from home every single day for many years to attend school and eventually university in Quetta, resolved never to set foot in a coal mine.

In February 2015, Gul’s family received news that his brother had passed out in a mine after a toxic gas leak. Though Muhammad survived, the incident so shook Gul that he decided he had to do something to improve the precarious conditions that Balochistan’s 300,000 coal miners worked in at 3,000 mines across the province.

Just last week, rescue teams saved two miners and retrieved the bodies of eight others after a methane explosion trapped the 10 in a coal mine in Balochistan. Safety standards are widely ignored in the coal-mining industry in Pakistan, leading to numerous deadly incidents.

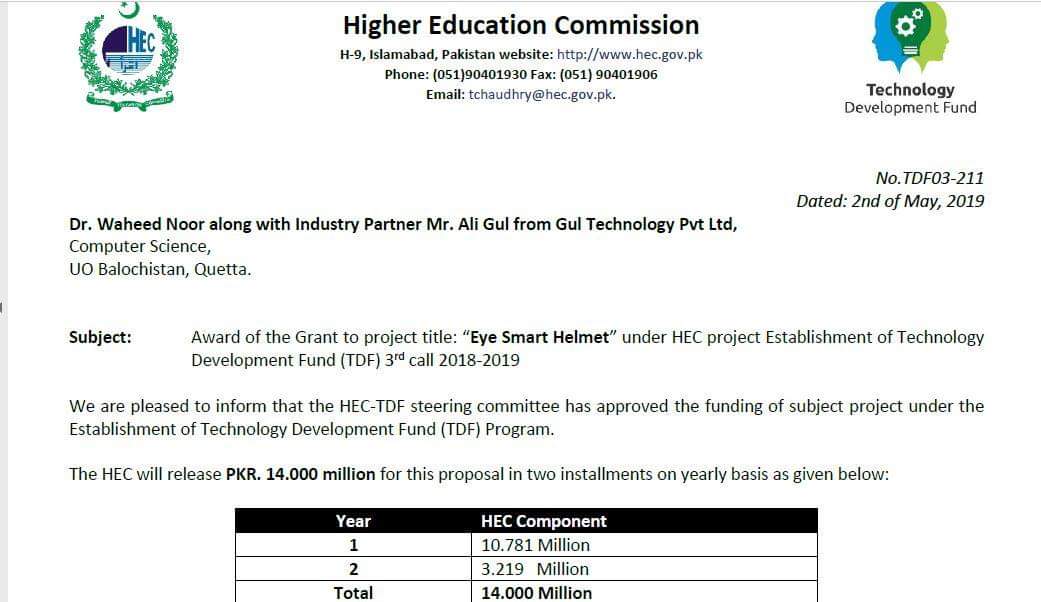

Ali Gul, a student of Balochistan University of Information Technology, Engineering and Management Sciences, works on the design of the Smart Eye Helmet project, which earned him a Rs14 million grant from Pakistan's Higher Education Commission on May 2, 2019: Photo taken on July 23, 2019. (Photo courtesy: Ali Gul)

“After my brother’s injury, I would think I have to do something to stop these lethal incidents from happening,” Gul, 24, told Arab News via telephone from Quetta. “It was usual for us to keep hearing about a new accident or that an acquaintance had died or was seriously hurt.”

When Gul moved to Quetta to study computer engineering at the Balochistan University of Information Technology, Engineering and Management Sciences (BUITEMS), his roommate, Gul Ustad, turned out to be a former coal miner himself, providing Gul with an even greater impetus to put his plan into action.

Soon after, Gul started to conduct research and found that at least 120 workers died on average each year in mining incidents in Balochistan. Gul thus began to work on a prototype for what would come to be called the Eye Smart Helmet: a special headgear that uses sensors to monitor mine conditions, the presence of toxic gases, explosion risks, and the location and health vitals of miners working in a particular mine.

Ali Gul, a student of Balochistan University of Information Technology, Engineering and Management Sciences, won a Rs14 million grant from Pakistan's Higher Education Commission on May 2, 2019 for his Eye Smart Helmet project to protect coal miners in Balochistan province, Pakistan. (Photo courtesy: Ali Gul)

Gul’s landlord in Quetta, who also happened to be a mine owner, saw the prototype of the helmet in his room one morning in 2016 and ordered him to make 20 samples. Gul delivered the order in 2017 but could not make any more helmets due to a lack of funds.

At the start of 2018, Gul took his helmet to Islamabad’s Startup Cup, a nonprofit venture that aims to foster entrepreneurial spirit in Pakistan. Here he met Jawad Khan and Muhammad Azeem who had brought their own startup, Qayaam, a platform for short-term renting, to the tournament. The three men got talking and exchanged numbers.

“His prototype was brilliant but he didn’t know how to generate funds,” Azeem told Arab News, saying him and Khan shared their number with Gul and they all began working together on the project’s financial assessment.

The teamwork paid off. In May this year, Gul and his partners won a Rs14 million grant from the High Education Commission (HEC), which will be released incrementally for product development between July 1, 2019 to June 30, 2020. Gul and his team will be required to conduct primary research on mines, working conditions as well as the nature of the work and of the mines. They will also use the funds to improve their prototype in light of their research findings before testing it in Balochistan’s mines. After a successful test, set to be carried out before June 30, 2020, the product will begin to be produced for commercial use.

In this photograph taken in January 2018, a coal miner at 98 Quetta Mine Area is wearing a helmet designed by Ali Gul, a student of Balochistan University of Information Technology, Engineering and Management Sciences, whose Smart Eye Helmet project won a Rs14 million grant from Pakistan's Higher Education Commission on May 2, 2019. (Photo courtesy: Ali Gul)

“This [helmet] will help us to save the lives of coal miners and enable owners to increase their productivity,” Gul’s colleague Khan said, adding that the headgear would also help predict mine collapses more accurately in the future.

“Once the project is completed, we will move toward the stage of mass generation and marketing,” said Azeem, whose role in the venture is to strategize and generate funds.

The team says though they have already been approached for orders by clients in Europe, their primary focus is Pakistan.

“We want to save the precious lives of our countrymen first,” Gul said. “We want to save lives and millions of rupees in losses and at the same time tell the world that there are some awesome, innovative made-in-Pakistan products available.”

Gul’s work, he says, is gaining in urgency as the number of mining deaths have gone up in recent years, from 120 deaths on average each year to 172 workers between July 2017-2018. Around 94 people have died in mining accidents in just the first seven months of 2019, according to the All Pakistan Labour Federation Balochistan.

“I had resolved as a young kid that I would never have anything to do with coal mines, that I would make a better life for myself,” Gul said. “I had never imagined I would even enter a coal mine. But now I have,” he said smilingly, “to take safety helmet for miners.”